| Software | |

|---|---|

| How ERP Software is Revolutionizing the Manufacturing Industry in 2025 | |

| Call Now | +91-990-404-0186 |

| +91-990-404-0186 | |

| Video Demo | Available |

| Eligible Region | India |

| Category | ERP Software |

| Payment Methods | Cash, UPI, Net Banking |

The manufacturing industry is undergoing a significant transformation in 2025. With the rise of smart factories, IoT integration, AI-based forecasting, and real-time decision-making, modern manufacturers need a unified solution to maintain control and growth. This is where ERP software has emerged as a powerful tool — connecting processes, people, machines, and data like never before.

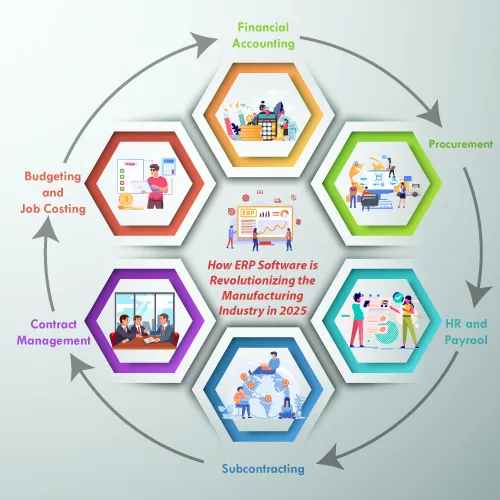

Today’s manufacturers no longer rely on isolated systems. They require centralized platforms that can handle production planning, inventory, procurement, quality, human resources, and finance — all under one digital roof. In this we’ll explores how ERP software is changing the face of manufacturing in 2025 and what decision-makers need to know to stay ahead.

Manufacturers are navigating a dynamic environment shaped by digital acceleration, customer expectations, and global competition. Some of the major shifts include:

Traditional manufacturing systems often fail to keep up with this pace, creating bottlenecks, inefficiencies, and data silos. That’s why businesses are rapidly adopting ERP software to build a more agile and connected operation.

ERP (Enterprise Resource Planning) is an integrated software solution designed to automate and unify business processes. For manufacturers, it means connecting every part of production — from raw material intake to shipment — into a single, coherent system.

When implemented correctly, ERP software can eliminate manual tasks, reduce production errors, cut lead times, and provide real-time insights for better decisions.

ERP isn’t one-size-fits-all. At Inniti Software, ERP is tailored for specific manufacturing industries:

This domain-driven approach helps manufacturers adopt a system that mirrors their unique operations — not the other way around.

A robust ERP software directly addresses these problems by creating a single source of truth across the organization.

At Inniti Software, we specialize in building ERP solutions tailored for manufacturers. With over a decade of experience, our software is built to handle industry-specific workflows, from batch manufacturing and compliance to HR and dispatch. We focus on simplifying your operations while giving you deep insights into every corner of your business. What sets us apart is our commitment to user-friendly interfaces, fast implementation, strong support, and powerful customization capabilities. We work closely with you to make ERP work the way you do — not the other way around.

As the manufacturing industry evolves, so must the tools used to manage it. ERP software is not just a system upgrade — it’s a complete transformation of how manufacturing businesses function in 2025. From inventory to HR, production to profit, ERP brings everything under one smart system. Companies that invest in a future-ready ERP solution are better equipped to handle disruption, increase efficiency, and scale faster in the competitive landscape.

For more details on how ERP software is revolutionizing the manufacturing industry in 2025, call us at +91 9904040186 or email us at info@innitisoftware.com.